History

Family Origins - Heaver Farms

The ancestral parentage of the Heaver family in Bosham can be traced back to Slaugham Manor, Sussex, where William Heaver (b. 1767) once occupied ‘lands, tenements, and hereditaments called Mill Hill Farm’. As a leasehold farmer initially serving Warden Sergison of Cuckfield Place prior to the estate’s timely disposal of title, William Heaver cultivated some 60 acres of wheat fields to supply flour to Chichester and its neighbouring towns. He and his wife Mary Anne Heaver (b.1775) bore one son, Thomas Heaver (1802-1882) after relocating to Ware, Hertfordshire, who later became a maltster and miller.

Thomas Heaver married Judith Maria Teed (1800-1870) and had two sons. Their firstborn, Thomas Teed Heaver (1840-1917) was a Reverend and notably an alumnus of Caius College, Cambridge; later a Curate of Southover Sussex and Dunston, Norfolk. Their second, John Heaver (1842-1885), acquired land and a tenancy at Broadbridge Farm in Bosham totalling 170 acres in June 1860 at auction in Chichester. Unfortunately, John Heaver died prematurely aged 43 leaving behind eight children – nine, if including Constance Lizzie Heaver (1869-1874), who perished at the age of five. Like her father and grandfather who were once churchwardens and major contributors to the community fabric of Bosham, Lizzie rests at Bosham Church, emphasising the historic and fulfilling relationship the Heaver family share with the village. Across generations of assistance provided to restore the Church and local facilities, the Heavers’ connection endures today with donations and the current John Heaver’s wedding in 2008.

The Milkmen of West Sussex

Despite his father’s relatively early passing, John Heaver’s eldest son John Wyman Teed Heaver (1866-1920) was instrumental in cultivating the family’s burgeoning reputation and diversifying the Heaver estate. Encouraged by his grandfather, the agriculturist and pragmatic entrepreneur explored ways in which new technology could maximise the productivity of his intensive farming methods before purchasing a dairy stock to manufacture and distribute milk and milk-based products. At a time of compulsory primary school education and increasing official intervention in the public diet (a re-energised Ministry of Health giving constant attention to the upbringing of a ‘healthy, sturdy population’) purchasing a dairy stock was an especially opportune decision.

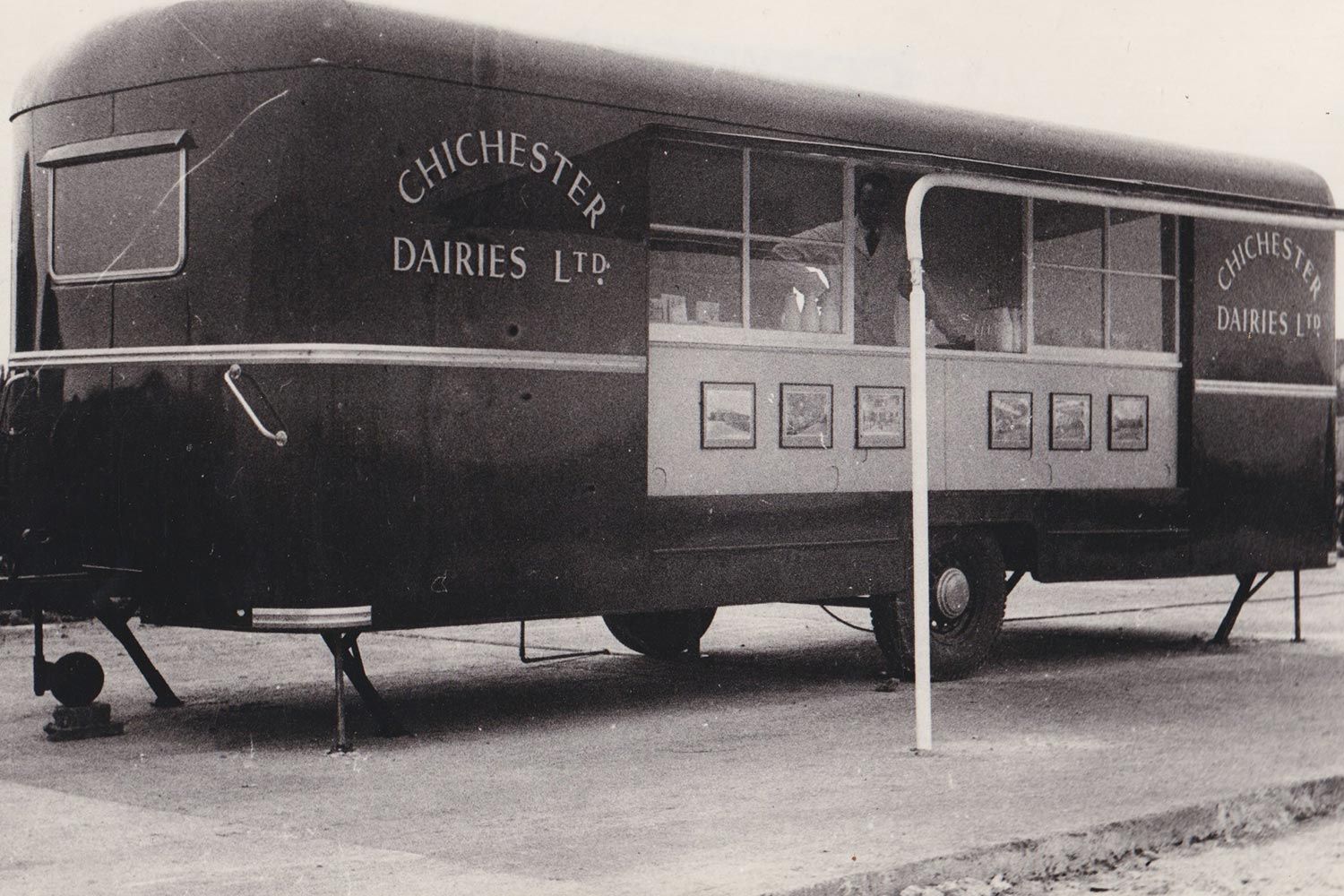

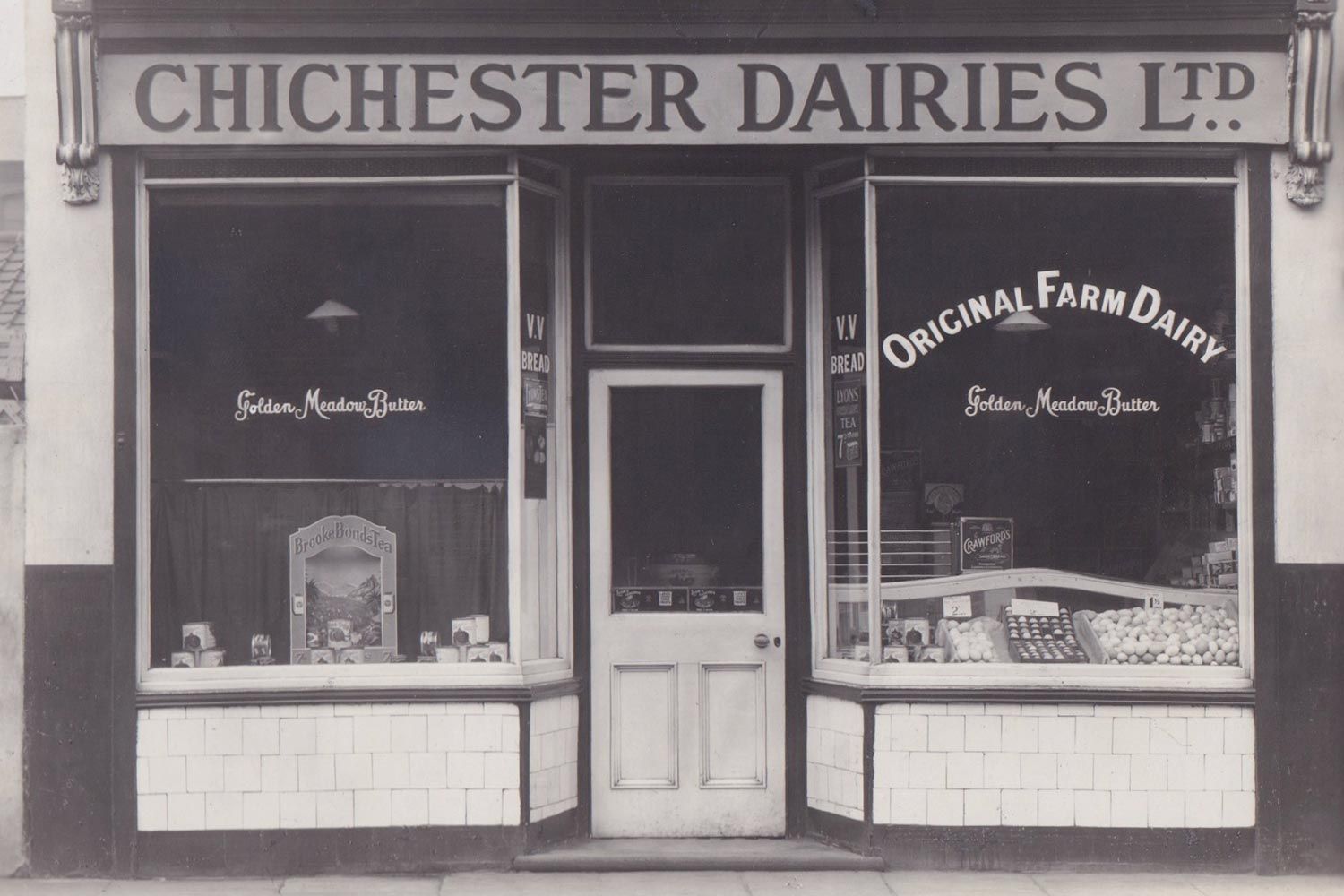

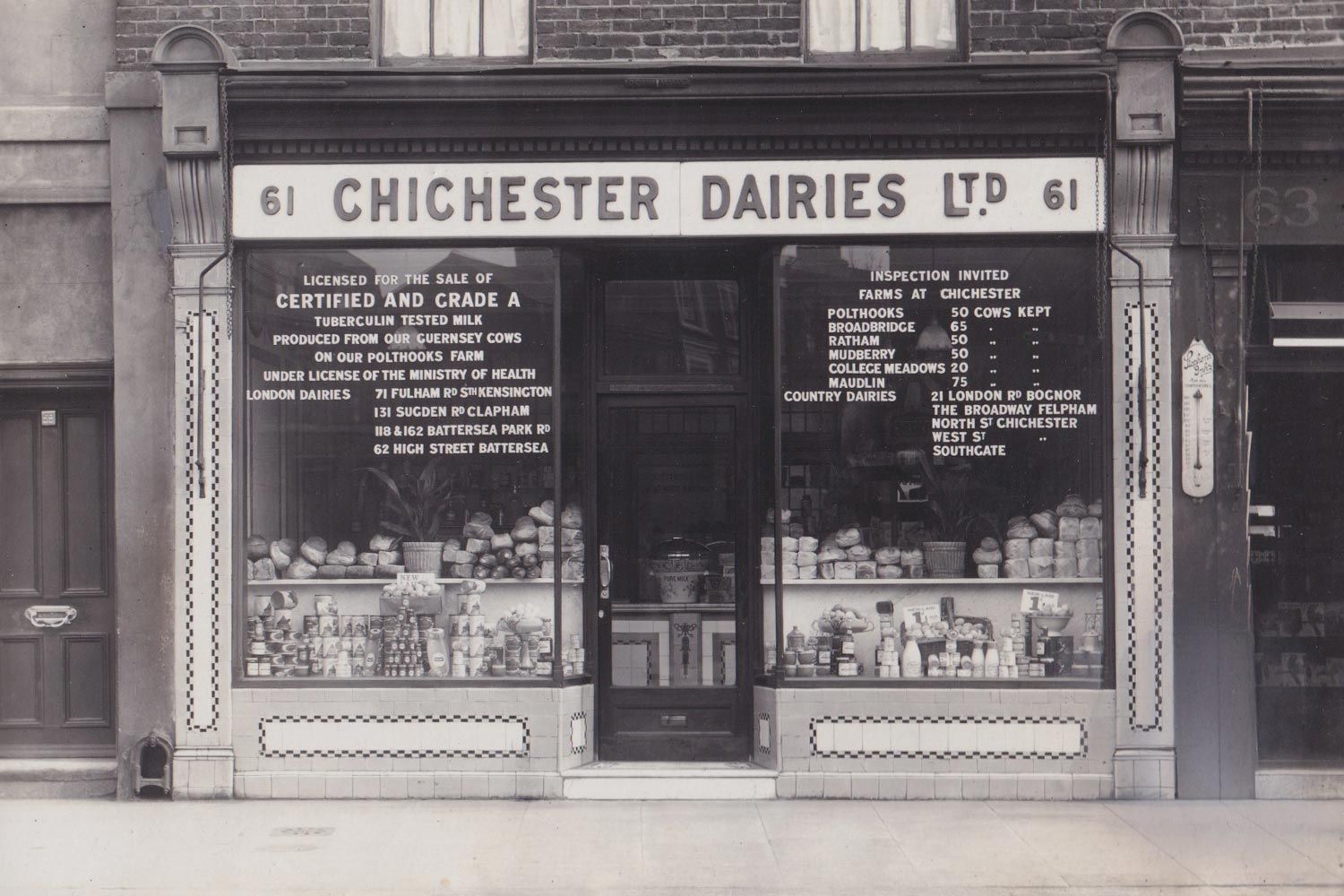

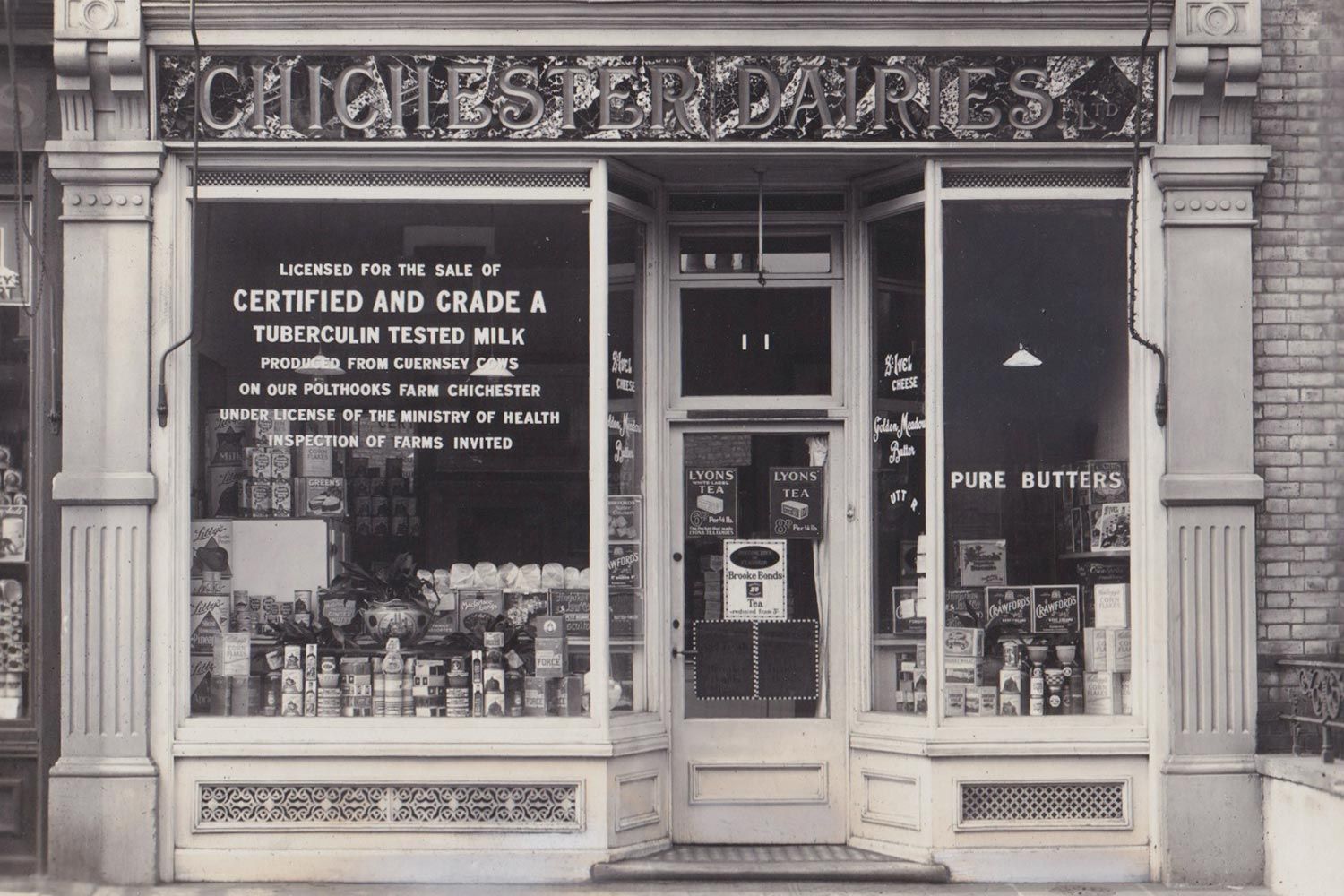

Even in light of a surging emphasis on nutrition, however, Heaver’s dairy operations had modest beginnings. We are fortunate that an early insight into the company’s origins is in fact revealed in The Sussex Express, July 8, 1899, where it is said that a ‘J. W. Teed Heaver, farmer and dairyman, of Bosham’ delivers ‘around the village’, and is ‘in the habit of des-patching two full milk cans by the up train leaving Bosham’. It is a positive indication that J. W. T. Heaver was delivering milk to Bosham’s local population well before the Great War (1914-1918). He went on to become a Guardian of the parishes of Westbourne and Bosham, subsequently rising to Vice Chairman of the District Council in the process and a Church Warden at Bosham. In a 1919 article published by The Observer and West Sussex Recorder, the logistical expansion of his dairy trade was such that in 1909 he founded ‘the Chichester Dairies Company’, having widened its distribution service to supply neighbouring towns. The stature of “Chichester Dairies” as a supplier of milk in West Sussex evolving exponentially in the turn of the century.

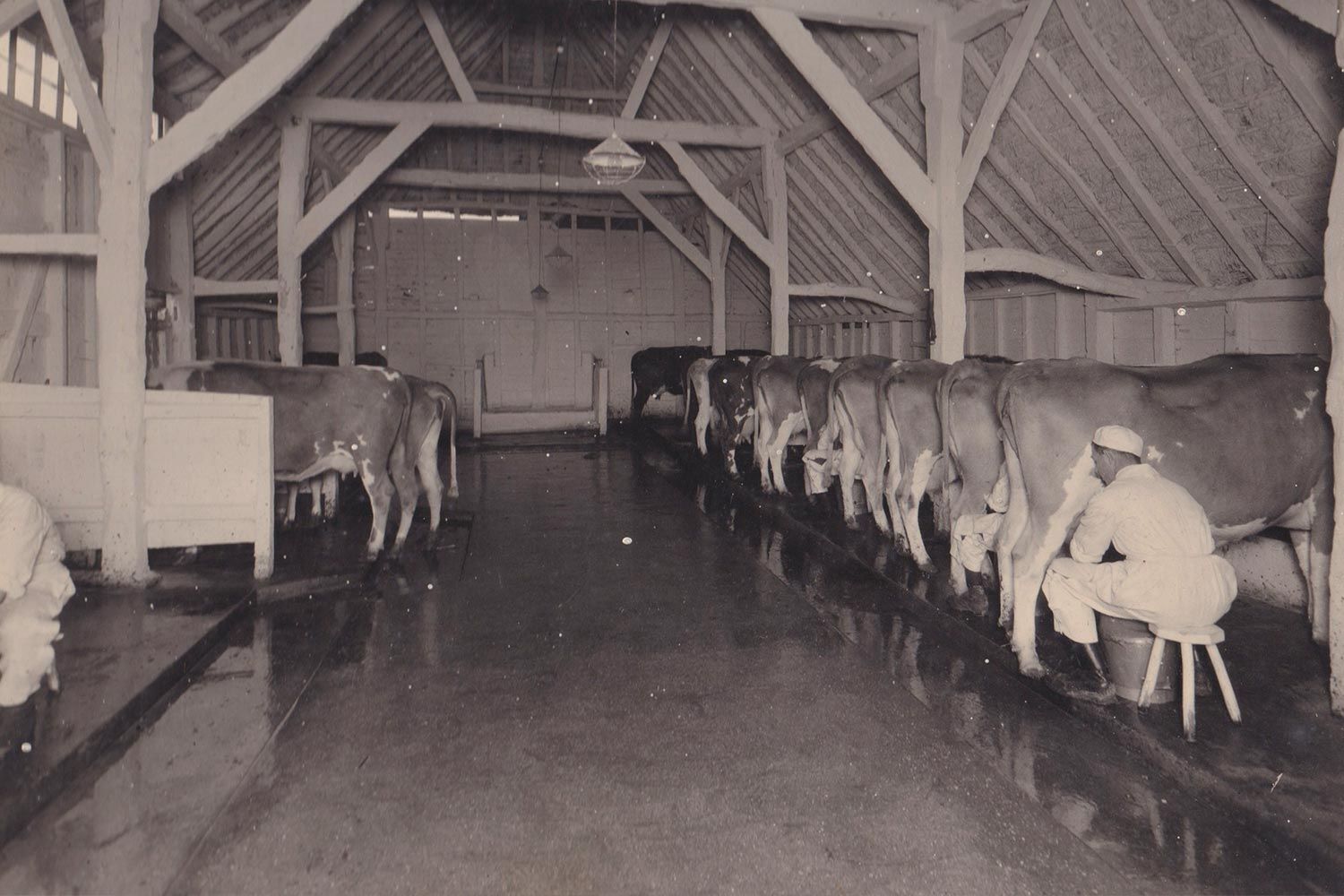

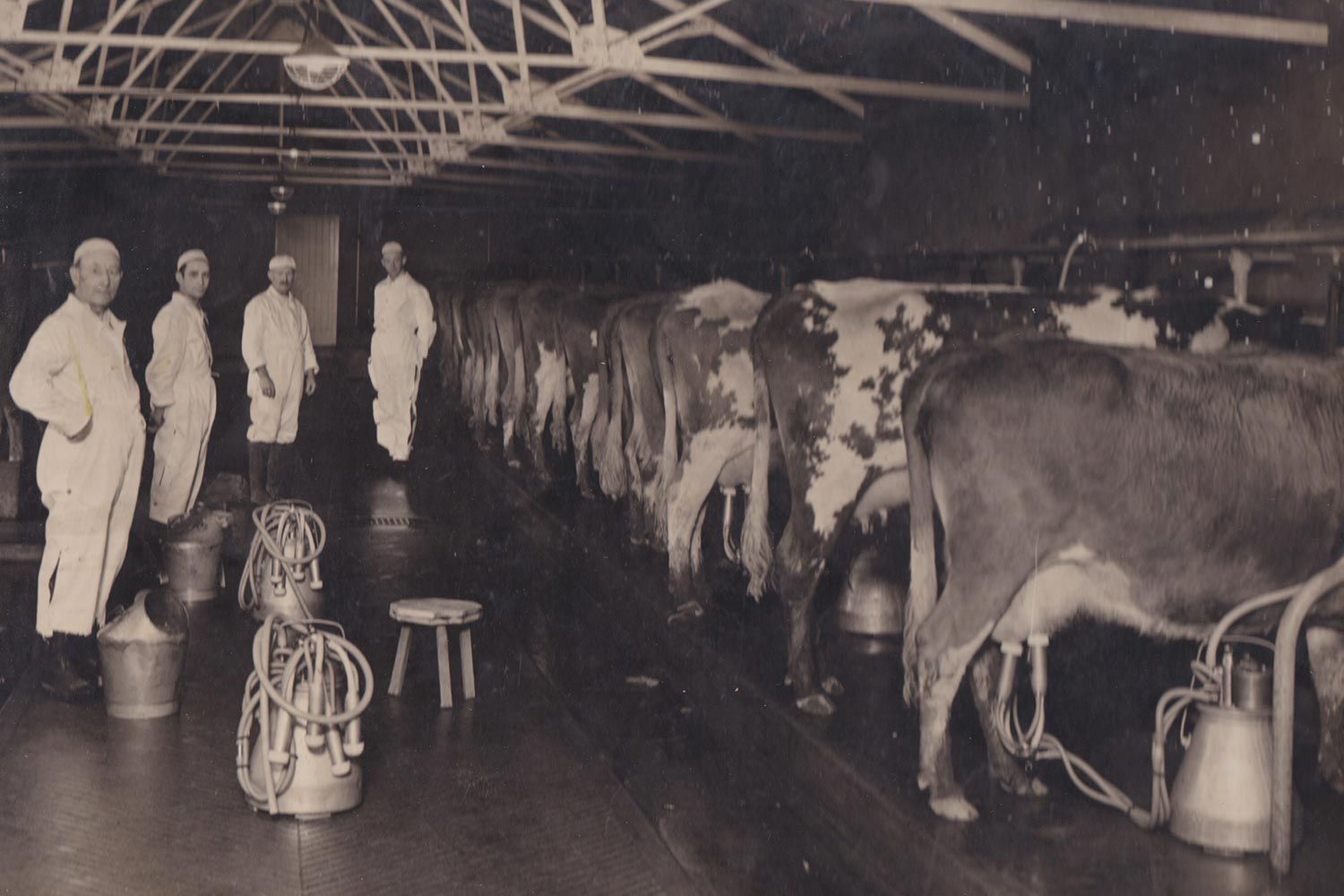

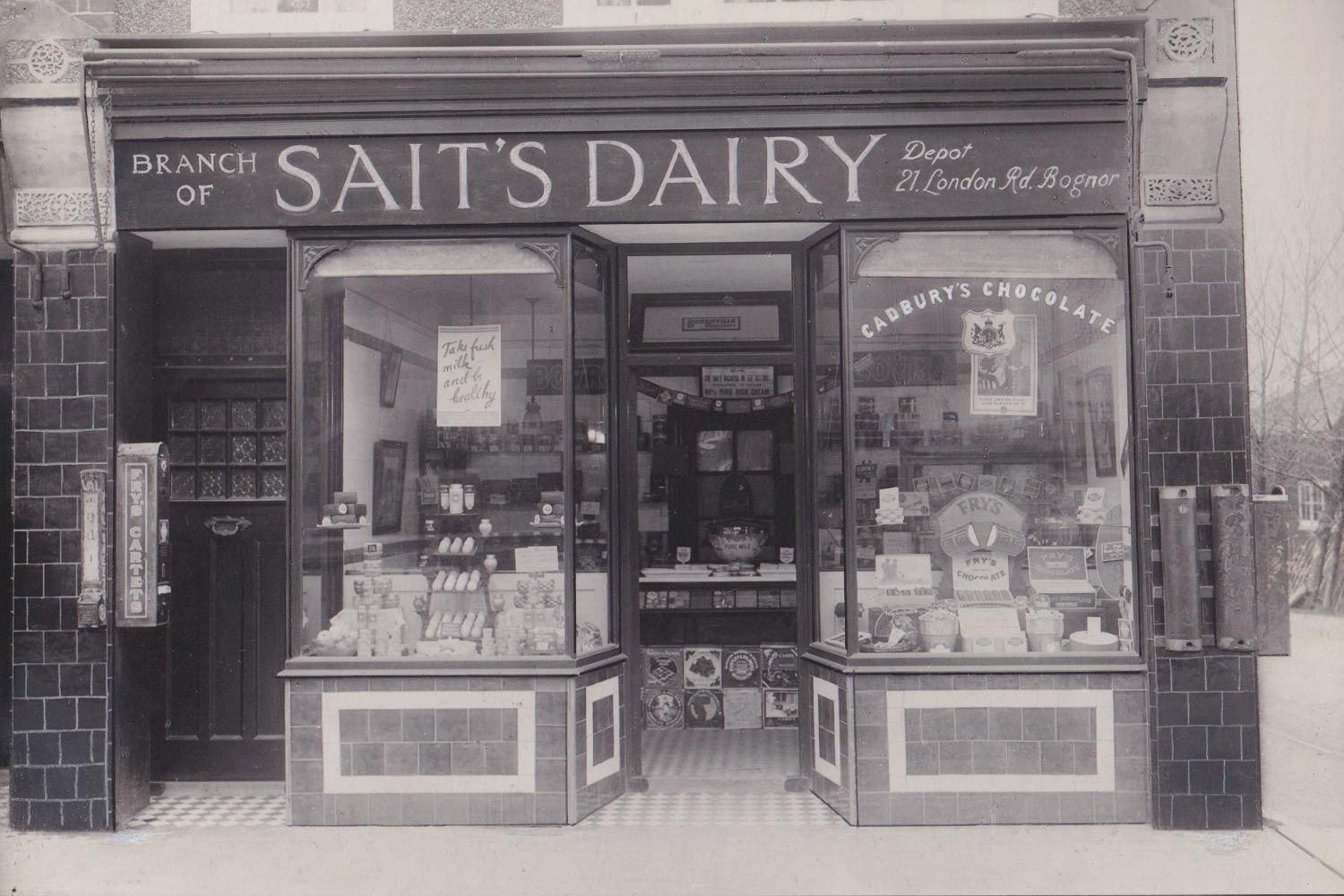

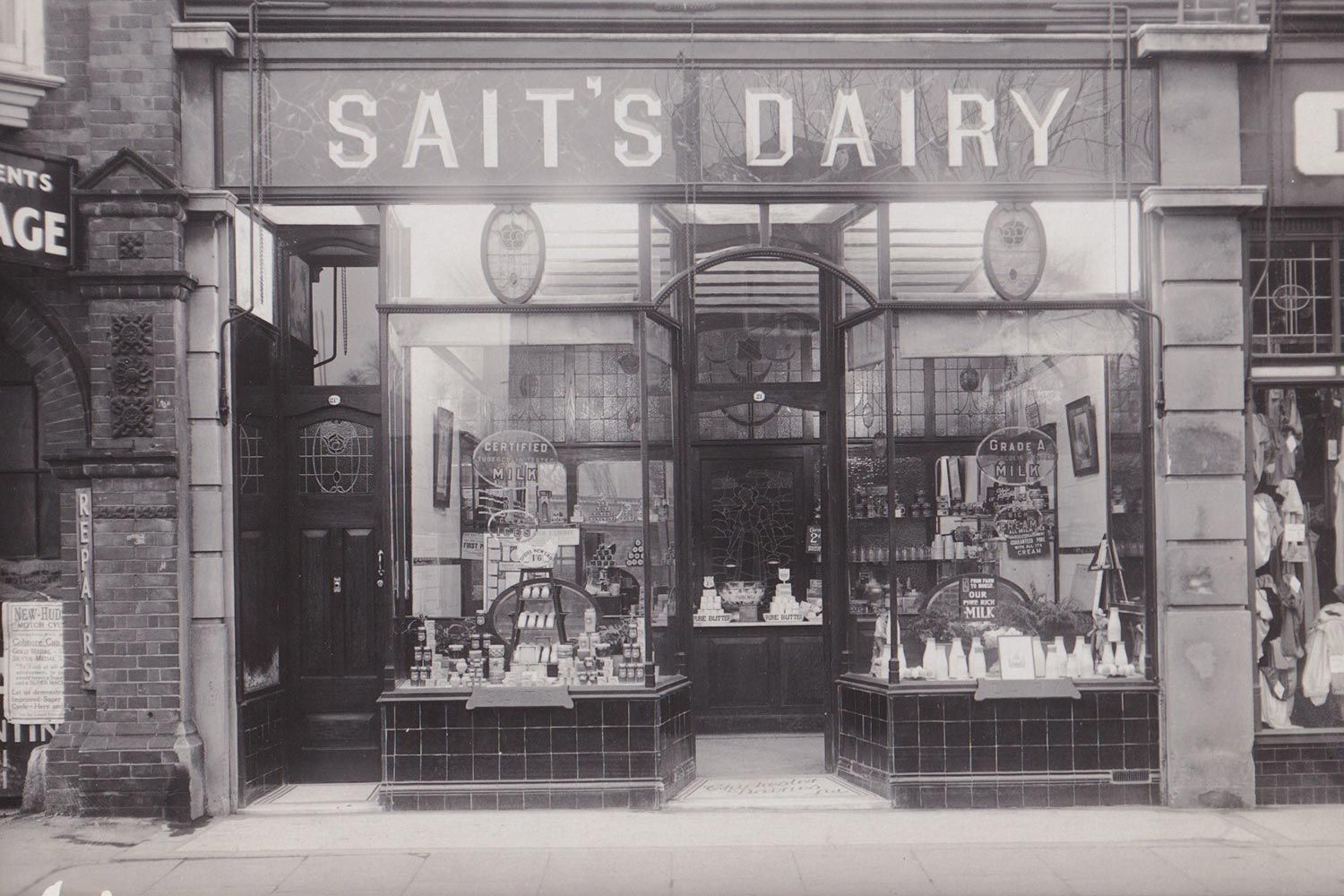

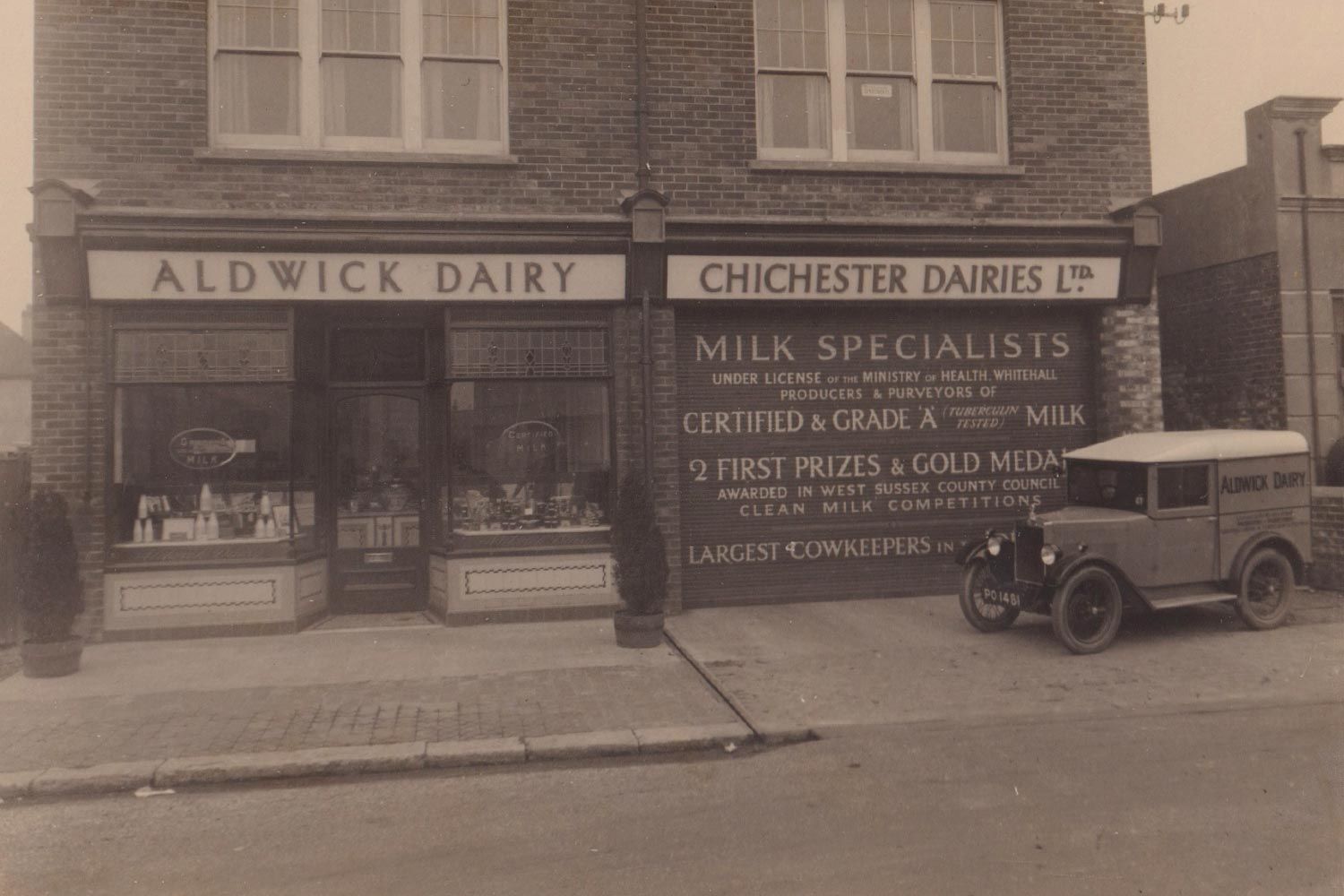

At a time of great competition between creameries with clearly defined spheres of influence J. W. T. Heaver’s rise to eminence was hardly guaranteed, and due in no small part to its emphasis on clean, pure milk with a longer shelf life that other brands in its regional space (notably Bognor-based Sait’s Dairies and J. M. Money Creameries) could not themselves achieve. A double-page spread in a 1925 issue of The Sussex Observer pays tribute to the Heaver families’ ‘dedication and care to strict hygiene’, a commitment which won them commendation from standard-bearers such as the National Milk Publicity Council, West Sussex County Council “Clean Milk Competition”, coveted “certified” standard from the Ministry of Health, and later presidency of the British Dairy Farmers’ Association.

Even as J. W. T. Heaver later passed the directorship of the business to his younger brother Thomas Douglas (1874-1957) following his incapacitation; this assurance to quality remained a core principle. Its success enabling the eventual acquisition of competing regional creameries including J. W. Money’s in Worth, Bognor-based Sait’s Dairies; Knapp, Fulham, Clapham and Battersea Dairies, as well as the Belgravia Dairy Company. Against the backdrop of what one commentator stated to be ‘growth of the business from small beginnings to extensive dimensions’, the Heaver family as an authority on dairy and a ‘keen judge of good cattle’ noted that production of clean milk ‘was not primarily a question of expensive buildings but dependent upon skill of the personnel and their methods’. The Heaver family established 90 milk rounds, 11 camp-sites along the south coast, a chain of high street shops, tea houses and hotels, and went on to become the third largest privately owned milk producers in the country.

Naturally, a resolve to supply a milk that is absolutely free from taint later commanded the use of advanced machinery, including a Turbine Plant for bottle washing, steaming chests for sterilisation of utensils used in its pasteurisation, and automation of the filling process.

Logistically, too, Chichester Dairies sought to complement mechanical milk floats with heavy carriers, branching out to complementary products such as thick cream, butter, and ‘eggs without qualification of any sort’. Such veterinary, sanitary and analytical supervision of an increasingly “bulk-and-carry” enterprise bestowed upon successors of the Heaver family skills transferable to heavy industrial production, including brick making and mineral extraction.

The Heaver's in Heavy Industry

While Chichester Dairies under the watchful eye of John , Thomas and later Jack Heaver became renowned for the breadth and quality of its distribution, the firm established premises in Bosham, Chichester, Bognor Regis, Selsey, Hayling Island, Middleton-on-Sea, Wickham, Farnham, Foumarks, Bordon, Clapham, Battersea, Elephant & Castle, Fulham and Kensington.

The family’s network of farms, included Broadbridge, Maudlin, Mudbury, College Meadows, Leythorne and Shopwyke, covering an aggregate area of 2,500 acres in West Sussex by 1920.

The Heaver’s entrance into gravel extraction was undoubtedly helped by an intricate understanding of complex logistics in the distribution of milk, which was not all that far off a “heavy” industry itself. In kind to the transportation of water, oil, and other liquids, the sheer volume of milk demand necessitated bulk haulage, as well as thorough investment in vehicles enabled to carry tremendous loads. At the very early inception of road locomotives the Heaver’s were already aware of the untapped potential for mechanisation, commissioning Burrell Showman to build the coal-driven Independence in 1919 for conveying road stone. An acute understanding of the need to systematise heavy road transportation bled into other industry standards that the Heaver family pioneered, including the ubiquitous use of wooden volume ‘computers’, or slide rules, to calculate concrete yardage. Only in the 1940s, however, did adequate technology exist to sustain inter-regional transportation of aggregates.

According to statistics from the Ministry of Transport and the Royal Institute of Hydrology, the newly-formed ‘John Heaver Ltd’ predominantly sourced fine flint gravel from pits east of Chichester for use as a compound in ready-mix concrete, a resource that was not only rare but also commanding of a substantial premium. The original locum of the pits can be gleaned from ordnance surveys available soon after the company was dissolved, that being pits south of Quarry Lane, Whyke which soon after expanded to encapsulate Shopwhyke, Portfield Works in Kingsham, and various large-scale pits that are now open waters including Leythorne, Peckham Lake, Vinnetrow, Runcton, New Lake, Copse Lake, East Lake, and West Trout Lake. In each of these excavation areas a steam dragline (consisting of a crane with an added winch drum unit for leverage) would be used, which at this time were some of the largest mobile land machines built.

Again revered for quality product as in the milk industry, the early-1950s saw the firm rise amongst competition to the forefront of gravel extraction, transporting over 170,000 yards of ready mixed concrete per annum aboard a formidable fleet which then included 34 truck mixers (AEC Mammoths, Dodge Rapiers, and Albion Caledonian tippers), 8 eight-wheelers and 2 bulk delivery eight-wheelers, distributing in Surrey, West Sussex and East Hampshire.

In the years after the Second World War, the Committee on Road Machinery after a visit to ‘Messrs Heaver’s Gravel Pit, Chichester’ that the operation was ‘seamless’, and a ‘credit to the hardy nature of the Sussex lot’. Indeed, by the 1960s John Heaver was an essential name in the creation of major trunk roads, most notably the Horsham bypass, Havant and other southerly bypasses along the A27 that now links Wiltshire with East Sussex where some 2 million tons of chalk and gravel was taken from Butser Hill to Portsmouth. At the extreme upper limit of road-based carrying capacity the tyre manufacturer Dunlop commented that the John Heaver gravel plant was ‘one of the largest in Europe’, cementing its identity as an esteemed institution in the movement of heavy minerals.

Given the sheer size of the draglines used in the excavation of gravel and their hybrid functionality in road construction and water-based dredging, it was not long after that horizontal integration enabled John Heaver to complement its equipment on land with a ‘menagerie’ fleet of sea-faring bucket sand or “sub-aqua” dredgers. Among those most well known comprised Debourne (104 tons), Endsleigh (104 tons), Viodon (165 tons) and Roway (120 tons), capable of extracting sediment from shallow waters using a mechanical pulley. Echoing the company’s desire to sit at the technological frontier of their enterprise, however, these units were later sold off and replaced by the 1,600 ton suction powered Chichester Cross, Chichester City, Chichester Gem and Chichester Star emblems of industrial pride and prowess in Sussex. The so-called ‘Marine Division’ was but one of an assemblage of specialisms under the ever-growing umbrella of John Heaver Aggregates, which at one point was the largest employer in Chichester.

John Heaver

John is a Chartered Surveyor and Farmer. He founded Heaver Agriculture, Heaver Commercial and Heaver Homes and stepped away from his role as an investment and asset management advisor in 2022 to focus on these businesses. He has a passion for wildlife and the environment and has experienced the positive effects real estate can have upon these and communities.

He has over 25 years of experience advising domestic and international investors on developments, acquisitions and dispositions. He has advised clients in countries including Australia, France, Greece, Hungary, Ireland, Italy, Japan, South Korea, Spain, the US and UK. He managed transactions exceeding £11 billion and oversaw £5.5 billion in assets under management within the warehouse, logistics, office, retail and hotel sectors.

Some example of John’s transactional experience include: